In 2021, the global economy suffered from regression due to the pandemic situation. Almost every enterprise has been downsizing to reduce costs; however, Fudy Group could move in the opposite direction. At this challenging time, Fudy Group has made strides and increased its investment. The newly-built functional printing and packaging BRC cleanroom not only shows Fudy’s expectation of innovation but, more importantly, satisfies the potential needs of customers and anticipates the future trends of the packaging industry.

Environmental sustainability has always been one of the core values of Fudy Group, this value has become a universal one to be reckoned with. To avoid environmental damage, Fudy is committed to eco-friendly manufacturing and green packaging[1]. Some people might think that packaging and environmental protection are two conflicting issues. Fudy, however, believes that the more we value environmental protection, the more attention should be paid to the quality of packaging so that the products are well protected with a lower attrition rate.

Fudy believes that future packaging should be more streamlined, efficient and eco-friendly. Besides, it should strive for exquisite packaging and create added value for products. Doing so increases consumers’ motivation to purchase products, expands the packages’ usage, and makes the packages keepable.

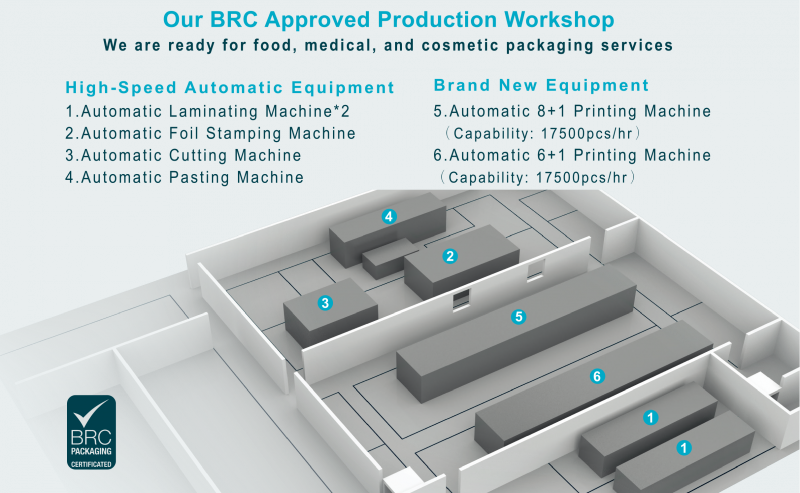

The new high-end printing and packaging BRC cleanroom at Suzhou Fudy’s factory is equipped with the latest and most technologically advanced machines[2]. It is not merely capable of making high-quality, appealing, and keepable packaging for products but also creating simple, effective, and waste-free packaging for the environment.

In the post-COVID-19 era, Fudy reflects on the kind of packaging consumers need. It should be safe, hygienic, and pollution-free. The packaging of hygiene-sensitive products such as food and cosmetics requires a system for strengthening safety and health management.

Fudy’s Suzhou factory’s new high-end printing and packaging BRC cleanroom adopts a one-stop design. All packaging processes are completed in this cleanroom, reducing the transfer path of products in the packaging process while minimizing pollution risks. The cleanroom also obtains the most globally recognized BRCGS PM certificate, making sure all packaging processes follow a step-by-step approach for the technical management of product quality and hygiene practices. It not only satisfies customers’ and consumers’ expectations but also demonstrates more trustworthy packaging.

Fudy believes that it has an obligation to provide safe and sanitary packaging to protect the products from any damage or pollution and reach consumers in good condition. The right packaging will illustrate the high quality of the products.

The Global Standard for Packaging Materials is the leading packaging standard of choice and is recognized worldwide. It was designed to protect the consumer by providing a common basis for the certification of companies supplying packaging to food producers and all applications at all supply chain levels. It specifies safety, quality, and operational criteria required to be in place within an organization to fulfill the obligation concerning legal compliance and protection of the consumer. The BRCGS standard is also recognized by the Global Food Safety Initiative (GFSI).

In a competitive market, the control of product information is of upmost importance. With any slight mistake, the hard work might be for nothing. In Fudy’s Suzhou factory, cleanroom information is kept confidential. Fudy has formulated a strict and rigorous packaging process that, from manufacturing to the scrapping of the defective products, keeps all the steps confidential. The confidential cleanroom[3], equipped with fingerprint locks, has a single-entry and a single-exit, also only approved staff have access to the cleanroom. It effectively reduces the risk of confidential information leaks.

The one-stop design makes it easy to keep close tabs on the packaging process. Meanwhile, the entire packaging process is recorded, which also helps mitigate the risk of information leakage. Fudy’s Suzhou factory can assuredly achieve the customer requirements for perfect packaging and confidentiality of product information.

—

[1] Green packaging uses materials and manufacturing techniques to diminish energy use and reduce the harmful impacts of packaging on the environment.

[2] Please see the picture of the machine configuration.

[3] Please contact Fudy Group for detailed confidentiality conditions

FUDY SOLUTIONS

FUDY SOLUTIONS 3054 Lawrence Expy Santa Clara, CA 95051 USA