Let’s talk about Paper structural packaging- Pack all Possibilities

The success or failure of packaging comes from two main elements: “material” and “structure.” Material and structure together decide the effectiveness of packaging protection, the convenience of product delivery, and level of consumer satisfaction. The result of this combination of premium material and intelligent structural design with excellent quality benefits business interests and brand image.

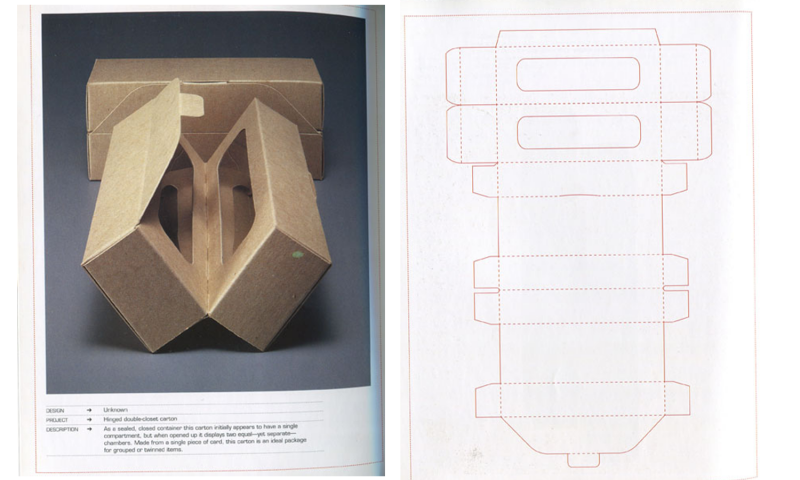

The term ‘packaging structure’ refers to the connections between the various elements of the product packaging.

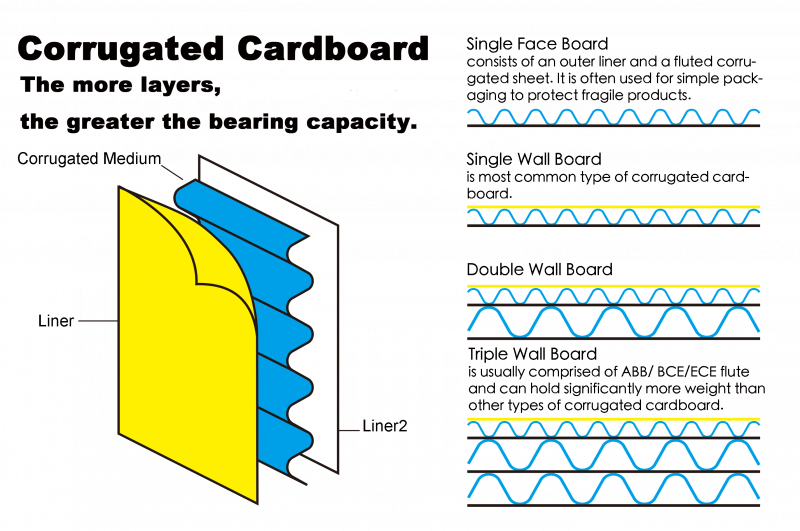

Paper is regarded as a green packaging material because of its light weight, cost-efficiency, high formability, and recyclability. Due to the characteristics of paper, paper structural packaging usually uses corrugated cardboard as the structure base to overcome the common challenge of insufficient resistance to pressure.

Corrugated cardboard is a structured industrial product. Combining structural rigidity with cushioning qualities, corrugated cardboard can effectively reinforce the packaging structure’s firmness and bearing strength.

Before a product reaches the consumer, it must go through numerous checkpoints including loading and unloading, transportation, and storage. Hence, protecting the product throughout this long process is the most crucial task of product packaging. Compared with inner protection layers such as Styrofoam or blister packaging, using paper as the main body of the packaging protection structure can effectively reduce the use of plastic packaging. However, the structural design requires careful calculation and planning by professional packaging structural designers. At the same time, innovative structural design ideas are necessary to create solid and eye-catching packaging.

Fudy Solutions works with many experienced structural designers who have mastered structural mechanics with innovative ideas and bold experiments. We are ready to provide you more possibilities for your product packaging structure.

Paper structural packaging has the advantages of eco-friendliness, lightness, and innovation. However, it usually requires some manual assembly which cannot be fully automated. Therefore, the manufacturing can be relatively time-consuming.

More to come. Less to waste.

“Fudy Group doesn’t own the copyrights for the following paper structural packaging design examples.”

Packaging is the first impression you make with the consumer, so let’s make it the first step of going green. Overproduction is costing us the earth. However, nowadays, it is pretty tricky for anybody, whether we are producers or consumers, to escape the cycle of production and consumption. How to make changes in this cycle and leave a ray of light for our planet is a question everyone needs to ask themselves,

FUDY SOLUTIONS

FUDY SOLUTIONS 3054 Lawrence Expy Santa Clara, CA 95051 USA