Molded pulp products (also referred to as molded pulp) are typically made from various natural fibrous materials, such as wood, bagasse, or reed; combined with non-fibrous materials, formed together by hot press molding machines. Products made with molded pulp materials are completely non-plasticized, this means eco-friendly packaging can be achieved without sacrificing the environment. Recycled pulp from recycled wastepaper can easily be used as the material for molded pulp products; thus, it is capable of being 100% recycled and reproduced. From raw material, production, waste management, remanufacturing— this perfect cradle-to-cradle cycle illustrates that molded pulp is a very sustainable packaging material.

In the early days, the colors of molded pulp products were relatively dull, the surface was rough, and the appearance gave people the impression of being unfinished and unpolished. However, after years of research and development efforts, molded pulp products can now be toned according to customers’ needs. Moreover, with the continuous improvement of technology, spray-coating techniques have developed significantly, and the mold manufacturing process has become more refined. Therefore, molded pulp products with a smooth and delicate surface can be produced. Nowadays, molded pulp packaging is very versatile and can be applied to a variety of products, from basic egg cartons to luxury packaging for high-end electronic products.

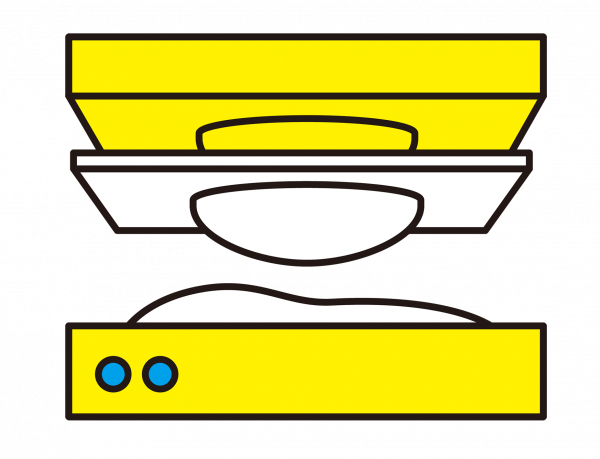

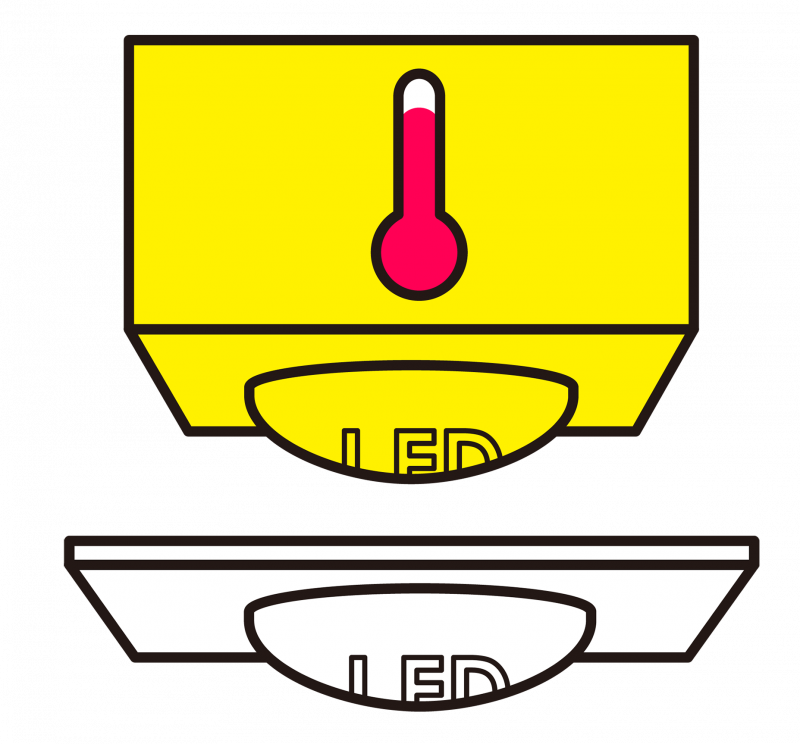

Molded pulp products are usually formed from a single piece of material, reducing the need for laborious installation works and other tedious processes. Through different designed molds, the pulp can be formed into different shapes in response to product needs, this illustrates its versatility. As the inner support of the product packaging, molded pulp inner trays can perfectly fix any product and strengthen the shock absorption and buffering capacity of the packaging through intelligent structural design to protect the product from damage.

Generally, molded pulp products are light, shock-absorbent and as they are molded from one piece of material, they are easy to store and stack, increasing space efficiency. In addition, the manufacturing process has a relatively low impact on the environment; with light materials, lower space requirement, and excellent shock-proof performance, molded pulp can be considered as one of the best choices of packaging. What’s more, the recyclability and reusability of molded pulp is in line with today’s trend for sustainable packaging. Fudy Solutions firmly believes that molded pulp will gradually replace plastic packaging and become the mainstream choice of packaging industry, shaping the future.

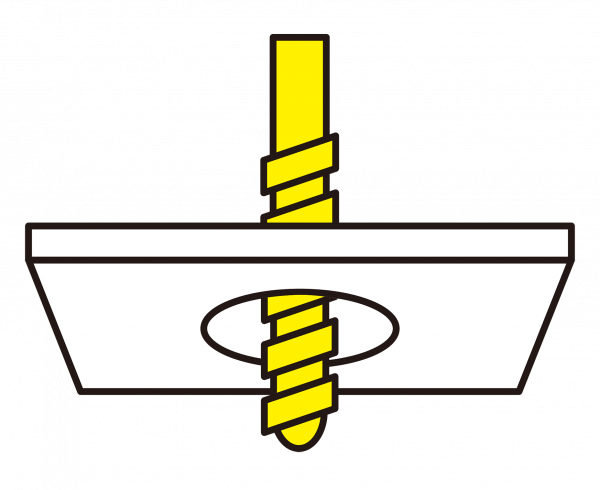

Mold design engineers are critical in the molded pulp manufacturing process, their contribution determines the success or failure of the packaging. Fudy Solutions has long-term cooperation relationships with many experienced mold design engineers. After the design is completed and a 3D model is created, Fudy Solutions closely coordinates with their customers and modifies the packaging based on their feedback. Not only do we offer quick proofing, timely production, and punctual delivery services, but we also have the most rigorous quality control processes in the industry. Thus, Fudy Solutions has the confidence to provide our customers with high-quality, delicate, and eco-friendly molded pulp packaging.

More Molded Pulp Tray case study.

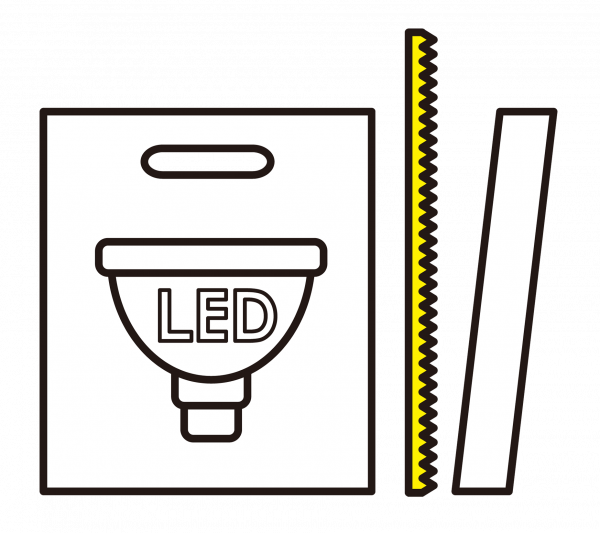

Laminate film is made of a base film coated with an adhesive. The composite material is used for a multitude of purposes because it provides a mixture of function, protection, and enhanced appearance choices.

Packaging is the first impression you make with the consumer, so let’s make it the first step of going green. Overproduction is costing us the earth. However, nowadays, it is pretty tricky for anybody, whether we are producers or consumers, to escape the cycle of production and consumption. How to make changes in this cycle and leave a ray of light for our planet is a question everyone needs to ask themselves,

FUDY SOLUTIONS

FUDY SOLUTIONS 3054 Lawrence Expy Santa Clara, CA 95051 USA