During the manufacturing process for the packaging of the Lily drone, it was our pleasure to develop and explore new possibilities in the realm of product packaging with our client. As our company motto implies.Power for the Possible!#minimalistic #newmaterial

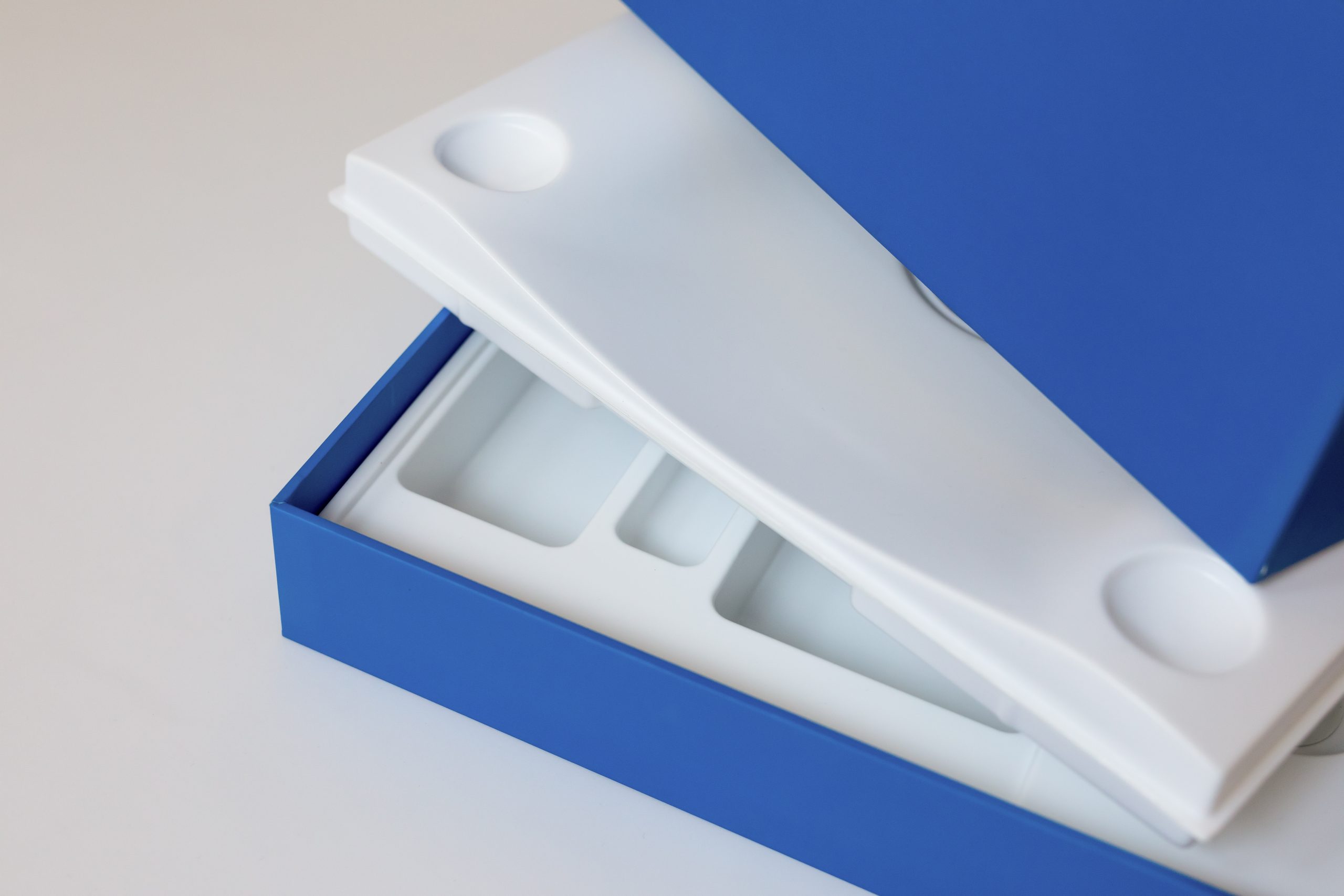

Lily Robotics is a newly established company based in Silicon Valley. The Lily drone comes with new functions such as hand toss to flight, automatic tracking and other functions not yet available on the market. As the company promotes innovation and daring to dream, a variety of different protective materials were used to try to create a new yet protective lining so that consumers may experience Lily’s innovative spirit from the moment they open the packaging.

Although the product promotes the idea of a palm-sized mini-drone, its 1.2 kilograms of weight may result in larger vibrations in transit. Lily also comes with multiple parts and is about the size of a burger with four foldable wings. Taking all of the above into account, how to incorporate sections of the packaging to stabilize the product within becomes the biggest challenge.

Various materials were experimented with to provide a protective lining. Multiple samples using PP, PET and PS were made. In the end, the lining of the cover was made through PP vacuum forming, and the lining of the bottom was made using two attached vacuum formed pieces of PS. The choice was made according to PP’s properties allowing for a more streamlined appearance while PS made it easier to mold cavities to support and stabilize the product within the packaging.

Cork was also considered as a possible lining material as its vibration damping and biodegradable properties as well as unique organic qualities make it extremely well-suited to this purpose. However, due to difficulties in obtaining large amounts of cork and high production costs at the time Lily entered the market and taking into account cork’s propensity to crumble, it was eliminated as a possible option. Nevertheless, it is worth noting that after many years of work and development, cork is now being incorporated into a variety of packaging for multiple products.

During the manufacturing process for the packaging of the Lily drone, it was our pleasure to develop and explore new possibilities in the realm of product packaging with our client. As our company motto implies.Power for the Possible!

We are Fudy, your product packaging consultant.

_

#PP plastic vacuum forming #PS plastic vacuum forming #hardcover #157gsm double copper #cork #bold colors

—

※ Copyright is held by Lily Robotics .

Designer: Ryan Kelly

Manufacturer: Fudy Solutions

FUDY SOLUTIONS

FUDY SOLUTIONS 3054 Lawrence Expy Santa Clara, CA 95051 USA