All of Fudy Group’s factories, spanning China, Taiwan, Vietnam, the United States, and Thailand, voluntarily follow the 5S/6S lean management as the basis for their management practices.

*Lean management can also be understood as on-site management of the workplace.

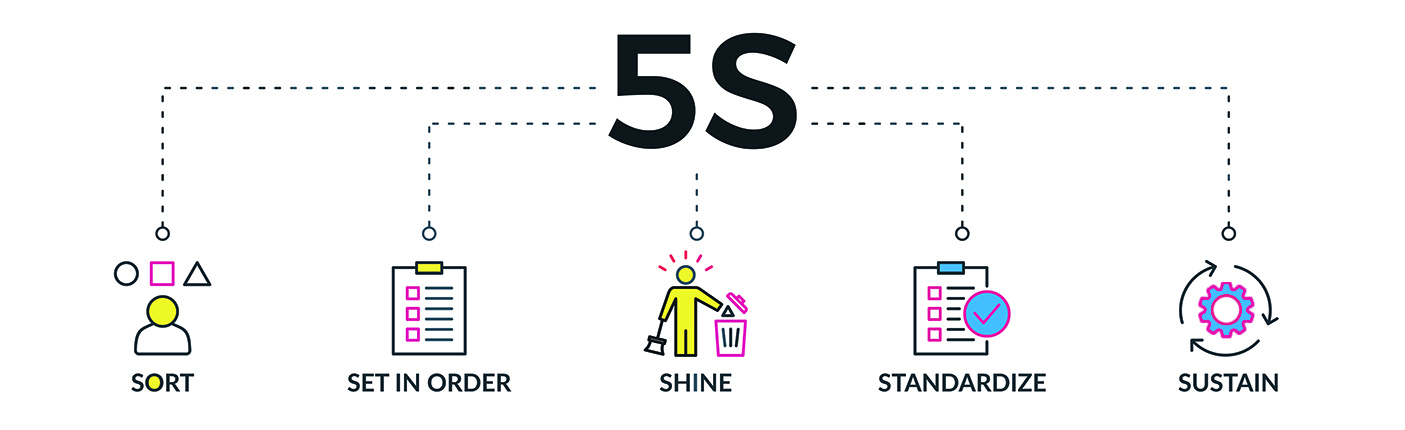

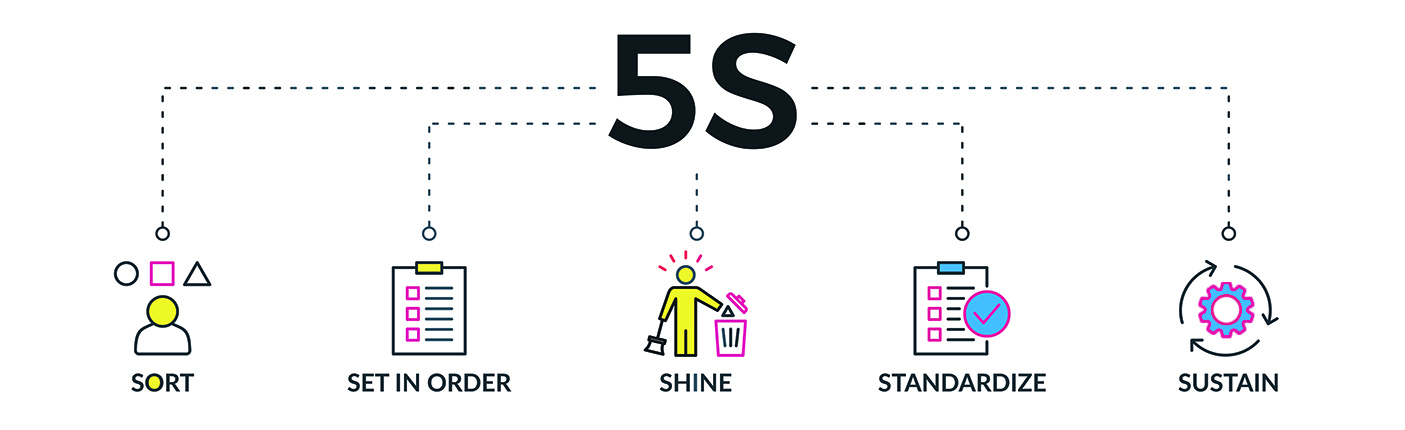

Initially, 5S refers to the five Japanese words which start with S :

Adding Security transforms the 5S‘s into 6s lean management

SOURCE: LEADERSHIP

A detail-oriented approach and high standards can foster good work ethics among Fudy employees, and good work habits determine work efficiency.

It is challenging to complete all the work without natural huamn errors. Therefore, good manufacturing management practices are crucial; implementing 5S/6S lean management can avoid making mistakes. Although we have high confidence in our colleagues, things could happen. Through monthly internal audits and real-time corrections, we strive to achieve PDCA (Plan, Do, Check, Action) self-management and improvement in daily work.

Power for the possible!

We are Fudy, your product packaging consultant.

FUDY SOLUTIONS

FUDY SOLUTIONS 3054 Lawrence Expy Santa Clara, CA 95051 USA