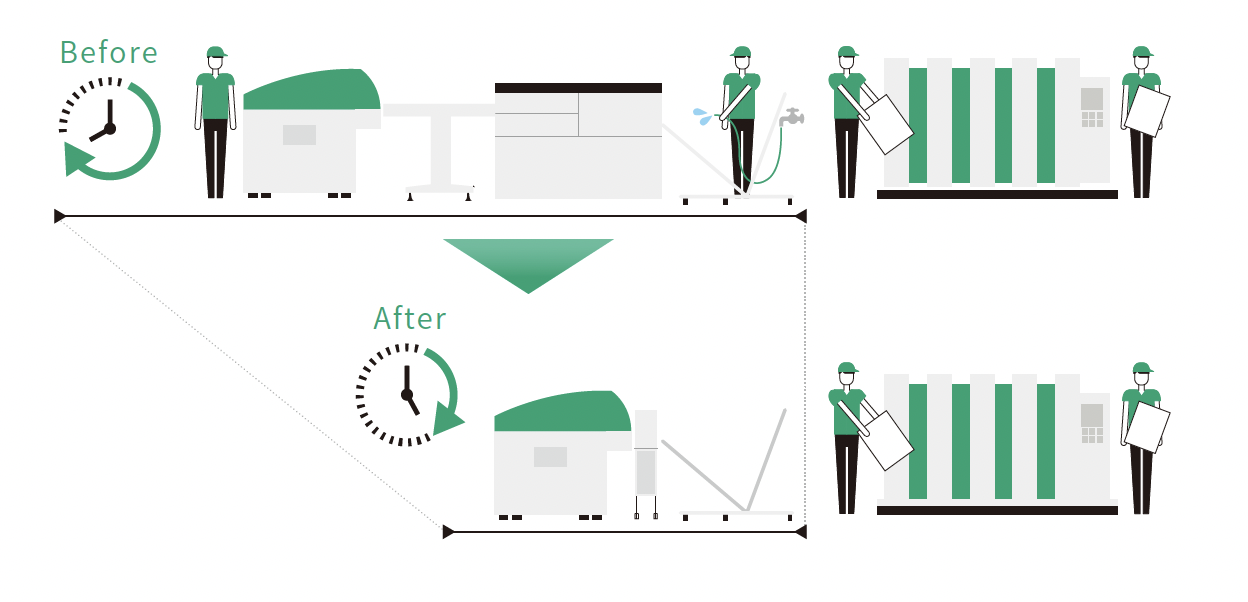

The traditional CTP (Computer-to-plate) needs to go through complicated procedures, including developing, rinsing, coating with protective glue, and drying the plate before it can be printed.

To complete the development procedure, a special liquid is required. The rinsing process consumes a significant amount of electricity and water. In addtion, this lengthy plate-making process also incurs costs related to cleaning and equipment.

The waste liquid produced by the plate-making procedure often has strong alkalinity. This is capable of causing damage to the human body and the environment, and therefore must be handled with care.

Packaging requires a highly complex manufacturing process. Fudy Group is committed to improving every aspect of this process. We believe that as long as a small step is made with each element, the entire packaging manufacturing process will show significant progress.

We wonder, how can we avoid the complicated plate-making process and reduce the potential damage to people and the environment and limit the pressure on resources?

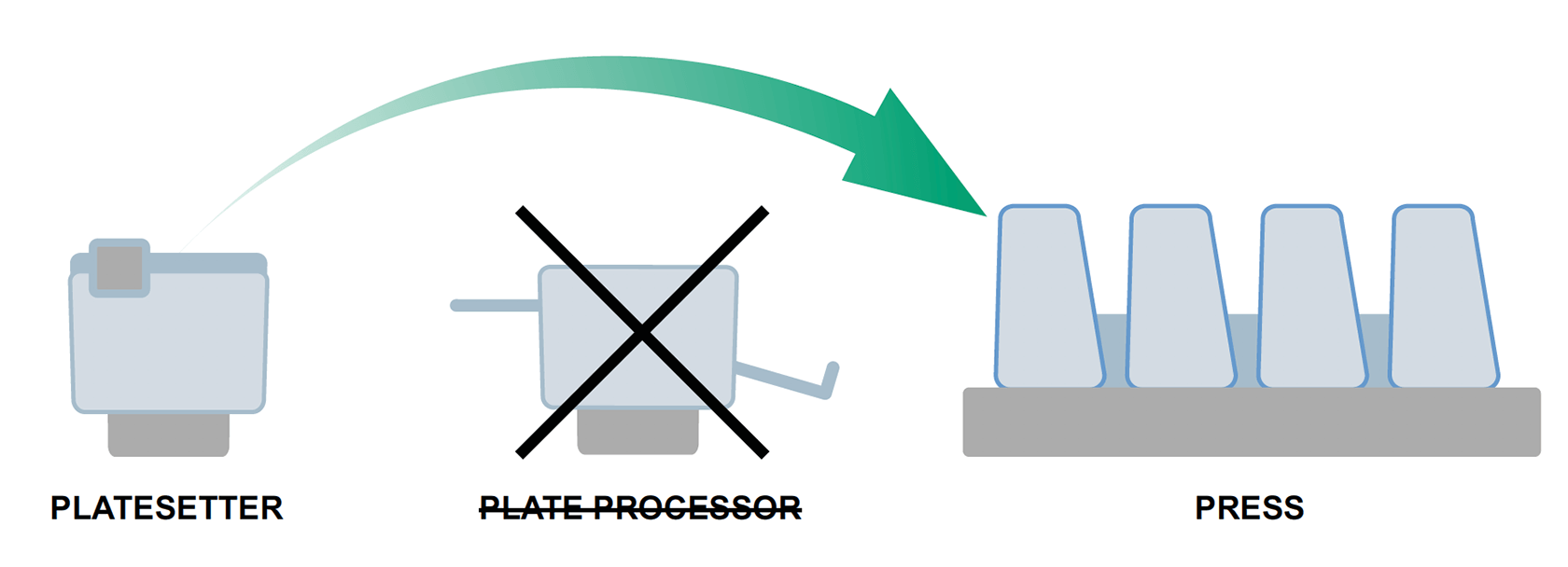

Fudy Group’s Suzhou Fuyang Factory has fully adopted the Fujifilm process free plate procedure which doesn’t need to be developed (to avoid using chemicals), nor rinsed (to save water), nor coated with glue. In other words, the Fujifilm process free plate procedure removes the complicated copying process of the traditional CTP and the accompanying potential pollution. On top of that, the best thing is that this new generation of rinse-free plates even fully meets the high standard of the printing industry.

Let us make better packaging and package your product better.

Power for the possible! We’re Fudy, your product packaging consultant.

SOURCE|FUJIFILM

Laminate film is made of a base film coated with an adhesive. The composite material is used for a multitude of purposes because it provides a mixture of function, protection, and enhanced appearance choices.

In 2021, the global economy suffered from regression due to the pandemic situation. Almost every enterprise has been downsizing to reduce costs; however, Fudy Group could move in the opposite direction. At this challenging time, Fudy Group has made strides and increased its investment. The newly-built functional printing and packaging BRC cleanroom not only shows Fudy's expectation of innovation but, more importantly, satisfies the potential needs of customers and anticipates the future trends of the packaging industry. Eco-Friendly Packaging is Critical

FUDY SOLUTIONS

FUDY SOLUTIONS 3054 Lawrence Expy Santa Clara, CA 95051 USA