Where there is consumption, there is manufacturing; where there is manufacturing, there is a product; where there is a product, packaging is required. As a leading pioneer in the industrial packaging supply chain, Fudy is best placed to understand how much resources are wasted in this interlocking industrial supply chain. At the same time, we also deeply understand that small changes can have a significant impact as long as we work to improve the manufacturing processes. By doing so, we can promote the concepts of sustainability, plastic-reduction, and net-zero emissions. Moreover, we can further create higher added value for the entire packaging supply chain and contribute to the sustainable circular economy of human society.

In addition to Fudy Group’s structural packaging design capabilities, we are also actively developing new environmentally friendly packaging materials. In 2010, we began to invest in sustainable recycling biomass technology and optimize our patent portfolio. Fudy Group invested in the team at Listen Green Technology to develop new eco-friendly materials. The multinational R&D team at Listen Green Technology experimented again and again, and finally making the waste in the ecological environment convert into a packaging material that can be mass-produced.

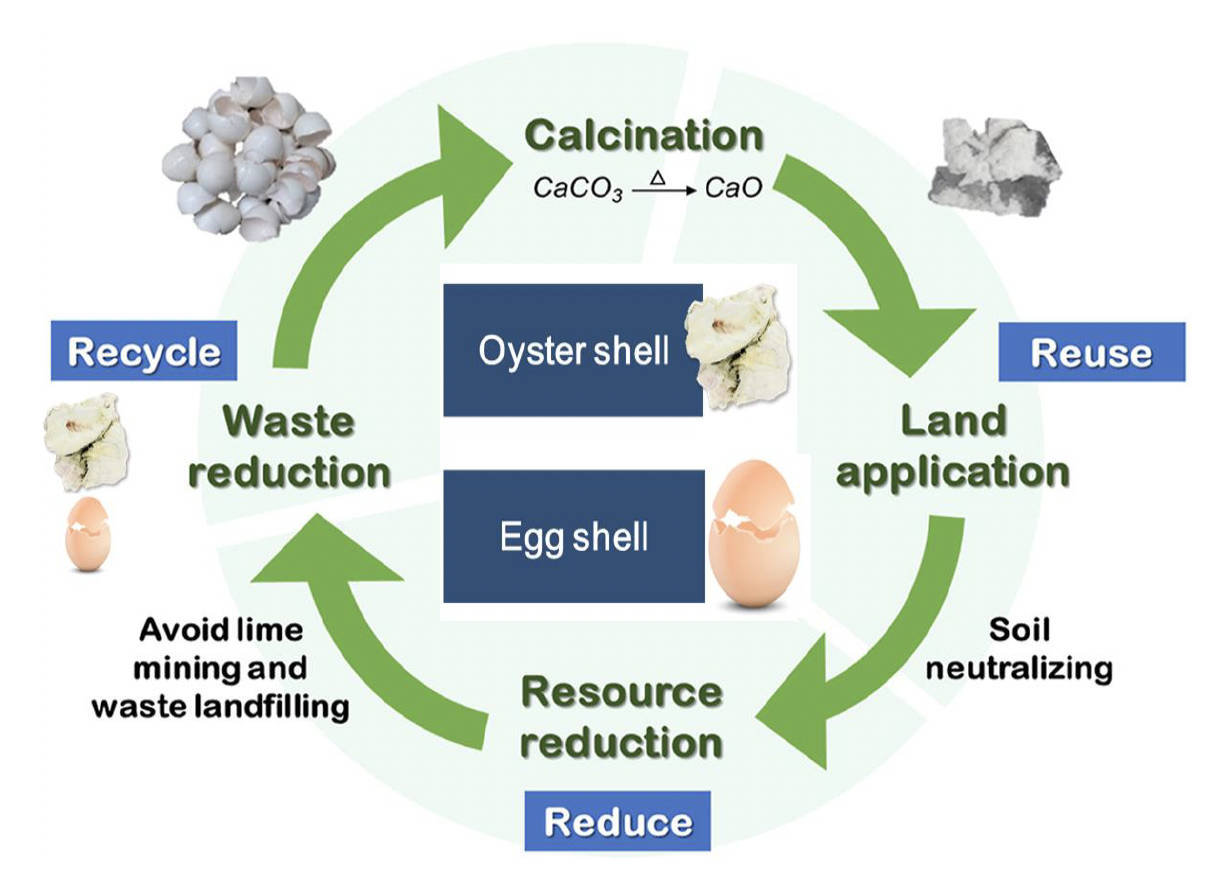

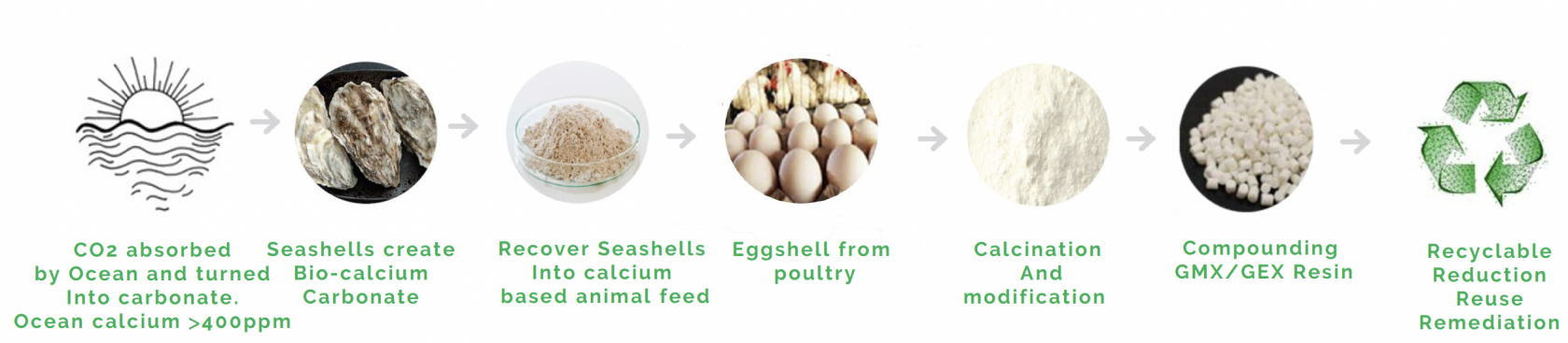

Oyster shells are usually seen as a natural waste. However, nowadays, new techniques can be used to convert oyster shells (marine calcium) into fertilizers and chicken feeds. After the feeds are consumed by the poultry, the ocean calcium will be transformed into eggshell materials (bio-calcium carbonate from eggshells). By doing this, the bio-calcium material (waste eggshells) is modified into bio-calcium GEX/GMX resins, which ultimately fulfills the sustainable life cycle ofwaste.

Bio-calcium GEX/GMX resins are widely applicable. The application range includes:

※ For a detailed classification of bio-based plastics, please refer to the article “Bio-based Plastic – Subtractive Technology for Plastic Packaging.”

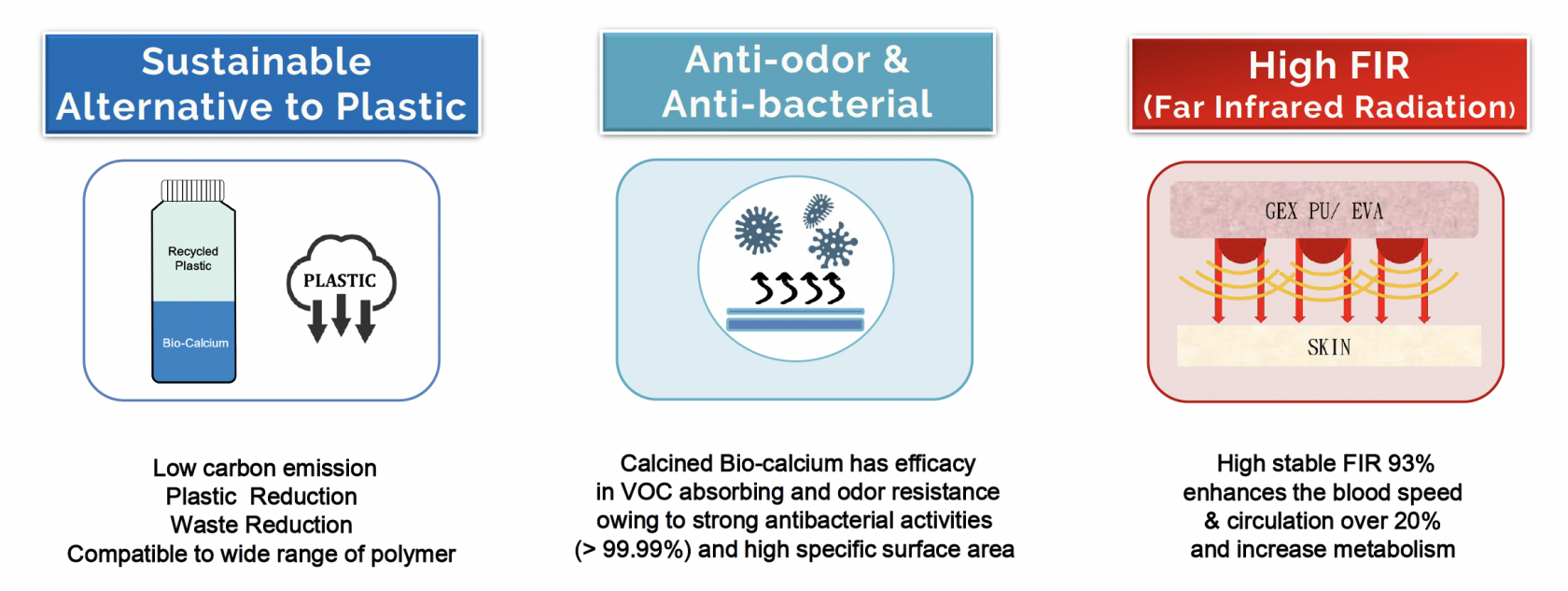

GEX/GMX bio-calcium resins have achieved SGS Eco Product certification and some international material testing certificates. Moreover, these kinds of resin have also passed SGS SVHC (Substances of Very High Concern) tests with 211 entries stipulated by the ECHA (European Chemical Agency). It meets the requirements of EU REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations and is an environmentally friendly, safe, and non-toxic biological material.

※SVHC (Substance of Very High Concern): Substances that cause risks to the environment and humans and raise significant concerns. Products containing SVHC need to fulfill corresponding responsibilities and obligations. With the progress of REACH, the ECHA (European Chemical Agency) publishes a new list of SVHC twice a year.

After years of research and implementation, GEX/GMX bio-calcium resin technology has matured and been introduced and used by international manufacturers in various industries. Fudy mainly applies this technology to different packaging materials, such as disposable, biodegradable plastic bags or multiple types of film, and uses GEX/GMX bio-calcium resins as substitutes according to customer needs, such as high-durability, carbon-reducing, and plastic-reducing packaging trays. We use sustainable recyclable packaging materials to fulfill our corporate social responsibilities in this industry. If there is a need for packaging using limited plastic, don’t hesitate to contact us. Let’s work together for a better planet, starting with thepackaging!

Power for the possible! We’re Fudy, your product packaging consultant. ![]()

SOURCE

FUDY SOLUTIONS

FUDY SOLUTIONS 3054 Lawrence Expy Santa Clara, CA 95051 USA