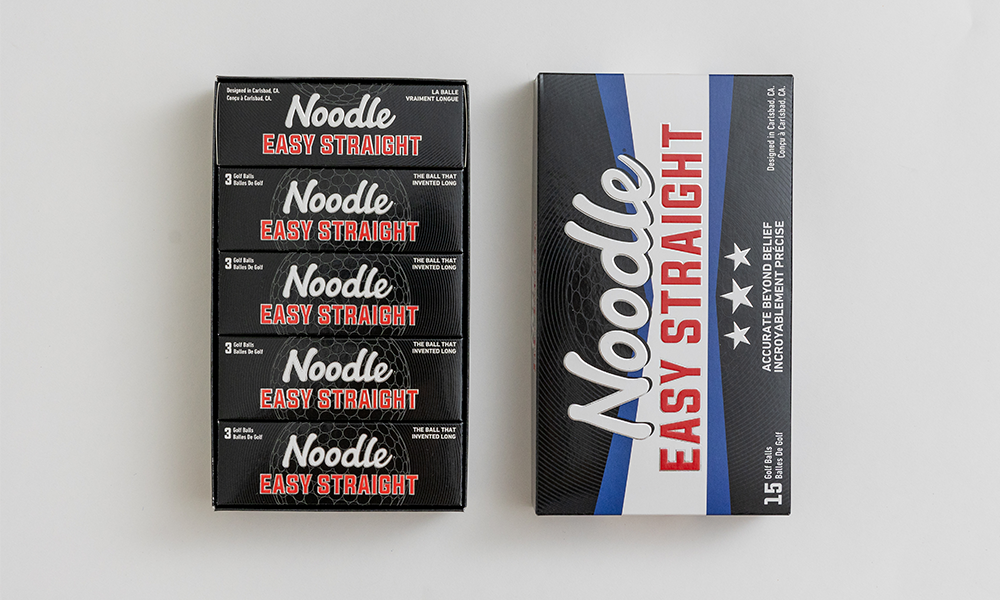

Three saturated colors distinguish the golf ball packaging with different characteristics. In addition, the printing processes, including embossing, hot foil stamping, and drip-off coating, are intended for packaging textural playfulness. The basic square box is conducive to automatic filling on the factory line, furthermore manufacturing is carried out in the most energy-saving and labor-saving way.

There are four small boxes contained within a big lid and base box. Although this kind of packaging box is basic, we used different printing processes to enrich the consumers’ experiences by employing strong visual and tactile details.

The printing processes include embossing, hot foil stamping, and drip-off coating. In this case, the most significant challenge was presenting the characteristics of these printing processes accurately and flawlessly.

Drip-off UV Coating | This coating uses gloss coating and matte primer, and the surface tension of the two different interfaces repel each other, producing light refraction to achieve the desired repellent effect. This method also causes the fine matte textured particles to attach to the printing surface. In areas where matte primers are not used, a glossy surface can be seen.Gloss and matte effects give this packaging a high-contrast visual effect.

Hot foil stamping | Hot foil stamping uses heat and pressure to apply metal film (usually aluminum foil) to paper.

In this case, the use of a silver stamping design is very restrained; only a delicate silver frame of about one millimeter is embellished next to the words. Therefore, accurate stamp alignment was crucial, requiring meticulous handling of every step in the printing process to work successfully. There can be no errors from pre-press to printing and post-press varnishing to ensure that the silver foil will be precisely and flawlessly aligned every time.

To facilitate the automation of packaging production, we employed a basic box type. However, different post-press processing methods have been used to enhance the packaging’s playfulness, this successfully causes this packaging to be both simple yet eye-catching. The overall packaging carries an American retro style reminiscent of 1950s superhero comic book design.

The Noodle is able to be a cost-effective, practical, and beautiful packaging product without sacrificing delicate details due to the need for automated production.

Power for the Possible!

We are Fudy, your product packaging consultant.

#300gsm C1S #Foil-stamping #Emboss #Drip-off UV Coating

—

Client:TaylorMade

Design by TaylorMade

OEM products, manufactured by Fudy Group / FUDY PACKAGING (TAIPEI) Co., Ltd.

FUDY SOLUTIONS

FUDY SOLUTIONS 3054 Lawrence Expy Santa Clara, CA 95051 USA